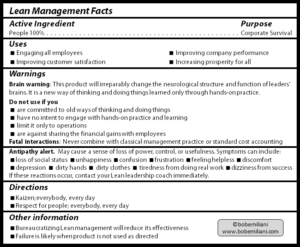

This Warning Label should have been attached to Lean decades ago. Everything contained in the warning label was understood 25 to 30 years ago.

But it was not attached to Lean. The result? Countless underdoses.

Corporate leaders did not know the facts about the product, Lean, before they started using it. They adopted Lean whatever parts of Lean they liked the most, which typically resulted in struggles and failures to achieve the Lean vision of a better workplace, a better company, and more satisfied customers.

The lack of a warning label resulted in harm to employees such as outsourcing, offshoring, layoffs of workers due to productivity improvement, and the termination of staff facilitating continuous improvement activities. This was caused by the zero-sum thinking that pervades classical management practice. Lean management is the opposite. It is non-zero-sum.

Warning labels are very helpful to people. But take helping people a step further. If you were to draw IKEA-like instructions for introducing Lean to people and implementing Lean, what would they look like?