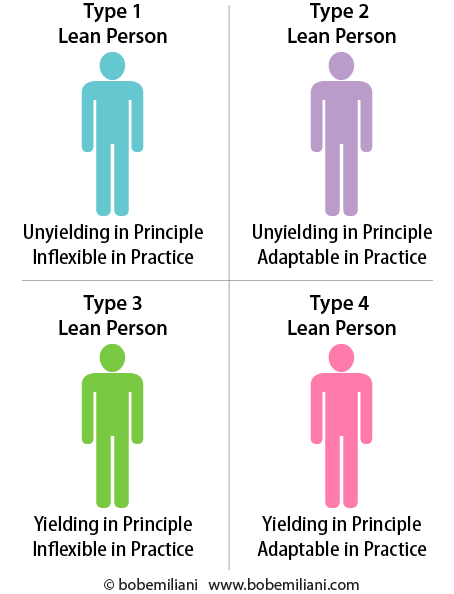

People who identify with Lean management or the Lean movement tend to be dedicated and very passionate, which generates a lot of arguments about right and wrongs ways to think and do things. Most of it has to do with how people understand the fundamental truths (principles) and how and when to use the methods and tools (practice). The principles are variously understood as Toyota Way principles — “Continuous Improvement” and “Respect for People” — or Lean principles as defined by Jim Womack and Dan Jones — specify value, identify the value stream, flow, pull, perfection — or a combination of the two. The existence of two sets of principles, confusing though it may be, is the reality of the situation. The practices are understood to be the various methods and tools found in Toyota’s management system that have been adopted by its derivative, Lean management.

The arguments that people have about Lean management are perpetual and resolution of conflicts seems impossible. The image above is intended to offer a classification of people by the nature of the work that they do — the underlying principle and practice that they employ to achieve improvements in business processes. Seen this way, the picture becomes much clearer. It is easier to understand the points of view of the people who argue the merits of their way of working towards improvement.

Is it fair to reduce people and their work to a 2×2 matrix? Yes, if it helps clarify and improve people’s understanding which, in turn, can lead to needed improvements in Lean thinking and practice. For example, this classification, rendered in a non-blaming and non-judgmental way, helps immensely to explain our empirical observations concerning Lean transformation process success and failure; we see much more of the latter than of the former. It is not so hard to imagine a company where the CEO is Type 4, vice presidents are Type 3, continuous improvement leaders are Type 2, employees are Type 3 and 4 — or other combination (you decide). How much success will the company have under such circumstances? How long will it take to produce good results? There will be Type mixes that produce good results and Lean transformation, and Type mixes that produce some improvement but no Lean transformation. You can look at this in terms of ideological alignment (or misalignment), if you wish, and envision the pace of change and learning that comes when people are aligned or not.

The image suggests to reflect on three questions:

The image suggests to reflect on three questions:

- What type of Lean person are you and how did you become that type?

- Did you evolve from one type to another over time?

- What type is best suited to lead Lean transformations?

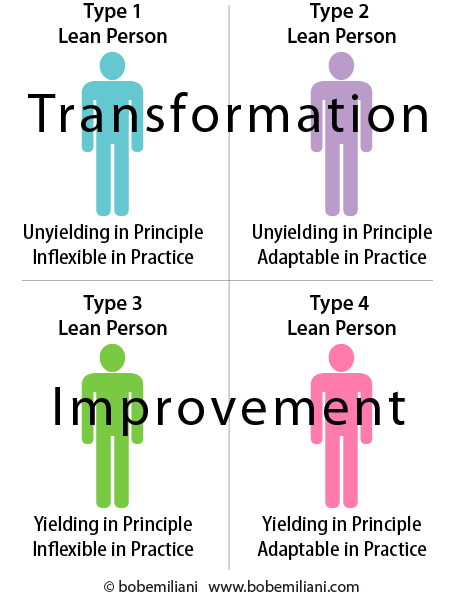

An honest assessment should lead to a realization that the work of Types 1 and 2 are most likely to produce transformation, while the work of Types 3 and 4 will result in isolated improvements. All four Types of Lean people are dedicated to improvement and have wholesome intentions. But the essential question is this: What is the goal? What result does the CEO want? In most cases, it is improvement, not transformation. Consequently, Type 1 and Type 2 Lean people are typically frustrated because they are unable to achieve transformation, while Type 3 and 4 Lean people are happy with whatever improvements they have been able to achieve. To them, this is success.

History repeats, not exactly, but closely enough to warrant our attention and to absorb some practical learnings. My construction of the top image was inspired by events that took place over 100 years ago as the leaders of the Scientific Management movement split into different groups with different aims and purposes. Frederick Winslow Taylor, the “Father of Scientific Management” was Type 1. His belief was that there was “one best way,” for “installing” Scientific Management. Henry Gantt, a longtime colleague Taylor’s and creator of many innovations including the “Gantt progress chart,” evolved into Type 2, as did Frank Gilbreth. Gantt’s view was that there were many ways to “install” Scientific Management, given the unique conditions that exist in each company.

Both Taylor and Gantt (and Gilbreth), using Type 1 and Type 2 work methods, successfully transformed several companies between about 1900 to 1919. But most business leaders did not desire transformation. Being Type 3, they instead, they adopted certain parts of Scientific Management and required strict adherence by supervisors and workers to the selected parts. Company leaders instituted a bureaucratic form of Scientific Management that resulted in “check-the-box” type of improvement work to demonstrate compliance. So-called efficiency engineers, management consultants of a variety different than Taylor or Gantt and Gilbreth, were mostly Type 4 (e.g. Harrington Emerson and especially Charles Bedaux). They did what their client, the top company leader, asked them to do — usually some short-cut, modified, or diminished version of Scientific Management. These consultants were adaptable in both principle and practice. They worked hard to deliver fast results to the company president — though often creating many new difficulties such as labor strife — got paid a lot of money, and moved on to the next client.

We see nearly the same things today. There are people like Taylor who are Type 1 — “Lean must be done this way in principle and practice!” The science says, “do it this way,” and so that is how it must be done. There are people like Gantt, Type 2, who are adaptable in practice but not in principle. They recognize the science (what the data says), but they acknowledge the importance of the art of human relations (psychology, respect, persuasion, buy-in, idea generation, etc.). Business owners and leaders, most often Type 3, want employees to rigidly apply the corporate toolbox and show conclusive evidence of its use to prove their individual worth to the company. This results in bureaucratic, check-the-box Lean, and (typically) little actual improvement. Type 4 can be employees or consultants who improve things under the rule of “business as usual,” making improvements where they can and with no illusion of seeking transformation. Classical management is the long-established system, not Lean management, and so improvement work must fit within the box of classical management so as to not disrupt the status quo.

Of course, some people change and evolve as they learn more. And so it is not uncommon for Lean people to go from Type 1 to Type 2 as Gantt did. In companies where production is a disaster, sensei may start out as Type 1 and change to Type 2 many months later as managers and workers demonstrate improved capabilities in understanding, practice, and results. Some people, impressed with Type 1 sensei, try to emulate them. That is usually a mistake because emulators do not have the knowledge, understanding, or experience to do it effectively and in a way that inspires confidence, respect, relationship-building, etc. Channeling Ohno-san is perhaps acceptable only for those now few people who actually worked with him. But then, even Ohno’s direct reports split up into Type 1 and Type 2 (TPS) people as time went on. And, generally, Type 2s can lay claim to longer-lasting successes.

In summary, I hope this blog post provides some useful information, past and present, to reflect upon as you move forward in your quest for Lean transformation, improvement, or whatever your goal happens to be.